Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Need to remove interior plastic rivets? This complete guide shows you the best methods. You can extract these fasteners without breaking your car trim or panels.

Using the wrong technique often leads to costly damage and broken clips. Our expert tips ensure a clean, professional removal every single time.

Best Tools for Removing Interior Plastic Rivets

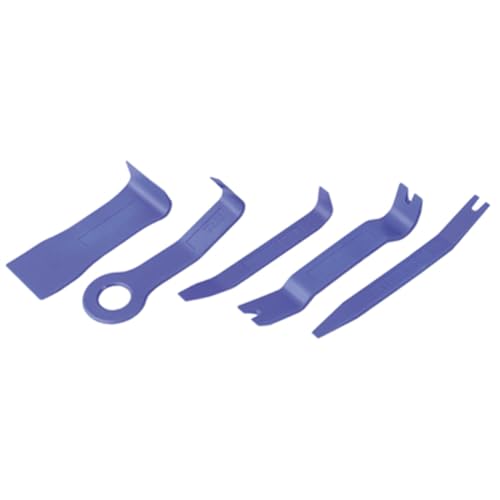

Having the right specialized tool makes removing plastic rivets simple and damage-free. We recommend these three proven products, each designed for different needs and budgets. They provide the precise leverage and gentle prying action required for this delicate task.

Keze 24Pcs Trim Removal Tool Set

This is the best overall choice for most DIYers and professionals. The kit includes twenty four different fork-style pry tools to handle various rivet and clip sizes. Its non-marring nylon construction protects your vehicle’s interior surfaces from scratches during removal.

- 11 Pcs Trim Removal Tool+1 Pcs Plastic Scraper:Made of High-Strength Nylon…

- 4 Pcs Precision Pick & Hook Set:Made of Carbon Steel, Sturdy and Durable,…

- Clip Remover Tool: Including 1 pcs 2 in 1 clip pliers, 2 Pcs fastener…

Lisle 83700 Interior Trim Panel Remover Set

Ideal for comprehensive interior work, this set features a sturdy forked tool perfect for rivets. It includes multiple pry bars and a handy hook tool. The ergonomic handles and durable build provide great control, making it a top recommended option for frequent use.

- Designed to remove fasteners on Door Panels and other trim

- comes with both U notch and V notch ends

- Tools can be stored in plastic tray

OTC 4489 Plastic Trim Fastener Remover

This is the best budget-friendly, single-purpose tool. Its simple, effective two-prong fork design slips perfectly under rivet heads. The compact size and robust metal core with plastic coating offer strength without the risk of causing cosmetic damage to your panels.

- Tools are made of plastic to prevent damage to trim, moldings, alloy wheels…

- Can be used on trim fasteners and moldings inside, or outside the vehicle

- OTC 4489 Trim Fastener and Molding Removal Set

Essential Tools and Materials for Plastic Rivet Removal

Gathering the correct tools before you start is crucial for success. Using improper tools like screwdrivers or knives almost guarantees broken trim. The right kit protects your vehicle’s interior and makes the job straightforward.

Must-Have Removal Tools

Your core toolkit should include specialized, non-marring pry tools. These are designed to apply force precisely under the rivet head without scratching surfaces.

- Plastic Pry Tool Set: A forked tool is ideal for prying up the rivet’s center pin. Nylon or coated tools prevent scratches.

- Trim Panel Removal Kit: These often include flat pry bars for lifting the entire rivet assembly from the panel.

- Needle-Nose Pliers: Useful for gripping and pulling the center pin once it’s partially released.

Helpful Supplementary Items

These items aren’t always mandatory but can save time and prevent frustration. They are especially useful for stubborn or aged fasteners.

- Panel Clip Remover: A dedicated tool that combines a fork and lever for seamless removal.

- Trim Fastener Repair Kit: Have spare rivets on hand. You will likely break some during the process.

- Flashlight: Improves visibility in dark footwells or under dashboards to see the fastener clearly.

Key Takeaway: Never use a metal screwdriver or knife. Always opt for non-marring plastic or nylon tools to protect your interior surfaces from permanent damage.

Plastic Rivet Anatomy

Knowing how these fasteners work informs your removal technique. A standard plastic rivet has two main parts that lock together.

The center pin (mandrel) expands the body of the rivet when pushed in. To remove it, you must first release this pin. The expanded body then retracts, allowing the whole piece to pop out freely.

Step-by-Step Guide to Removing Plastic Rivets Safely

Follow this proven method to remove interior plastic rivets without causing damage. The process requires patience and the right technique more than brute force. Working systematically ensures your trim panels remain intact and unmarked.

Initial Inspection and Preparation

Always start by identifying the rivet type and its condition. Look for the small, often cross-shaped, head of the center pin. Clear any debris from around the rivet with a soft brush.

Gently probe the area with your fingernail or a plastic tool. This helps you understand how the panel sits and where to apply pressure. This crucial step prevents unnecessary stress on the surrounding plastic.

The Core Removal Process

This numbered sequence is the safest way to extract a standard push-in plastic rivet. Work slowly and deliberately for the best results.

- Release the Center Pin: Insert the forked end of your pry tool under the pin’s head. Apply gentle upward pressure until the pin pops up about 2-3mm.

- Pull the Pin Out: Use needle-nose pliers to firmly grip the now-exposed pin. Pull it straight out until it detaches completely from the rivet body.

- Remove the Rivet Body: With the pin removed, the rivet’s legs will collapse. Use a flat trim tool to gently pry the entire rivet body out of its hole.

Pro Tip: If the center pin spins but won’t pull out, the legs are likely still engaged. Stop pulling and re-insert your pry tool deeper under the rivet’s base flange to release more tension before trying again.

Handling Stuck or Broken Rivets

Age and weather can make rivets brittle. If a rivet breaks, don’t force it. Instead, use a small drill bit (often 1/8″) to carefully drill out the center of the remaining piece. Drill slowly to avoid damaging the panel’s mounting hole.

For a rivet that won’t budge, a precise application of heat can help. Briefly use a hairdryer on a low setting to warm the plastic. This can make it more flexible and easier to remove without snapping.

Common Mistakes and Pro Tips for Success

Avoiding common pitfalls is key to a clean removal process. Many DIY errors stem from rushing or using improper force. Learning from these mistakes will save you time, money, and frustration on your project.

Critical Errors to Avoid

These mistakes frequently lead to broken trim, damaged panels, and stripped fastener holes. Being aware of them is your first line of defense.

- Prying from the Wrong Angle: Never pry against the painted or visible surface of the trim. Always insert your tool parallel to the panel and lift from underneath the rivet’s base.

- Using Excessive Force: If the rivet isn’t moving, reassess your technique. Forcing it usually breaks the rivet or the panel’s mounting tab, creating a need for complex repairs.

- Ignoring the Center Pin: Attempting to pry out the entire rivet without first removing the center pin is the most common cause of failure. The pin must be extracted to collapse the rivet legs.

Advanced Professional Techniques

These expert tips go beyond the basics for handling tricky situations. They help you work smarter, not harder, on any vehicle interior.

For rivets in extremely tight spaces, try a modified hook tool. You can bend a small pick or dental tool to create a custom implement that slides under the pin head where standard tools won’t fit.

Keep a magnetic tray or small container nearby. Immediately place all removed pins and rivet bodies into it. This prevents lost small parts from falling into door cavities or under seats.

| Problem | Likely Cause | Quick Solution |

|---|---|---|

| Pin spins but won’t pull out | Rivet legs are still fully expanded and locked. | Pry up under the rivet’s outer flange to release leg tension, then pull pin. |

| Rivet body won’t come out after pin removal | Legs are stuck due to corrosion or dirt. | Spray a small amount of silicone lubricant around the base, wait a minute, then try prying again. |

| Trim panel feels loose after rivet reinstallation | The replacement rivet is the wrong size or the mounting hole is damaged. | Use a slightly larger diameter rivet or a trim clip repair washer to fill the enlarged hole. |

Reinstallation and Replacement of Interior Plastic Rivets

Properly reinstalling or replacing rivets secures your trim and ensures a professional finish. This final stage is just as important as the removal process. Using the correct technique prevents rattles and a loose, unfinished appearance.

Choosing the Correct Replacement Rivet

Not all plastic rivets are the same. Using an incorrect size or style will result in poor fitment. Always match the new fastener to the old one as closely as possible.

- Measure the Shank Diameter: This is the width of the part that inserts into the panel hole. Common sizes are 4mm, 5mm, and 6mm.

- Check the Head Style: Match it to be flush, countersunk, or decorative. The head must sit properly against the trim surface.

- Note the Length: The rivet must be long enough to fully engage the panel and its backing structure without bottoming out.

Step-by-Step Installation Guide

Installing a new plastic push rivet is simple when done correctly. Follow this sequence for a secure, flush fit every time.

- Align and Insert: Place the rivet body into the clean mounting hole. Ensure it is straight and the flange is seated against the trim.

- Push the Center Pin: Using your thumb or a small, flat tool, press the center pin firmly into the rivet body until you hear or feel a distinct audible “click”.

- Final Check: Gently tug on the trim panel near the rivet. It should feel solid with no movement. The rivet head should be flush with the surface.

Installation Tip: If a mounting hole is slightly enlarged or damaged, use a trim clip repair washer. This small plastic ring fits around the rivet shank to take up slack and restore a tight fit.

When to Use Alternative Fasteners

Sometimes, a standard rivet isn’t the best solution. For access panels you may need to remove frequently, consider quarter-turn Dzus fasteners or Velcro. These allow for easy, tool-less repeated access without wearing out the mounting points.

For a permanent repair on a stressed panel, a plastic weld or two-part epoxy may be more appropriate. Assess the function of the panel before choosing your final fastening method.

Specific Applications and Vehicle-Specific Advice

Removing plastic rivets can vary slightly depending on their location and your vehicle’s make. Different areas of the interior present unique challenges. Adapting your approach ensures success across all common repair scenarios.

Common Rivet Locations and Strategies

Identify where the rivet is located to choose the best removal angle and tool. Each area requires a slight modification to the core technique.

- Door Panels & Kick Plates: Rivets here are often under tension. Support the panel with your free hand while prying to prevent stress cracks. Work from the bottom upward.

- Headliner & A-Pillar Trims: Use extra caution due to fragile materials. A wider, flat trim tool distributes pressure and prevents fabric tears or creases in vinyl.

- Under-Dashboard & Console Areas: Visibility is poor. Use a mechanic’s mirror and a headlamp. Be mindful of wiring harnesses and cables directly behind the panel.

Dealing with Different Rivet Types

Beyond standard push-pin rivets, you may encounter specialized designs. Recognizing them prevents damage.

Expansion Rivets have a smooth, dome-shaped head with no obvious center pin. To remove, you must carefully pry up the entire outer edge of the rivet head evenly with a flat tool until it releases.

Christmas Tree Clips are often mistaken for rivets. These are removed by gripping the base firmly with pliers and pulling straight out, or by prying up the center post with a small screwdriver.

| Vehicle Type | Common Consideration | Expert Recommendation |

|---|---|---|

| Older Vehicles (10+ years) | Plastic becomes brittle with age and UV exposure. | Apply gentle heat with a hairdryer for 30 seconds to increase flexibility before attempting removal. |

| German & European Models | Often use unique, proprietary fastener designs. | Invest in a brand-specific trim removal kit or consult a model-specific forum for precise tool advice. |

| Modern Cars with Advanced Safety | Side airbags (SRS) may be housed behind trim panels. | Always disconnect the vehicle’s battery and wait 10+ minutes before working near door panels or pillars to prevent accidental deployment. |

Safety First: When working near airbag components (SRS), always disconnect the battery. This is a non-negotiable safety step to prevent serious injury from accidental deployment.

Maintenance and Prevention for Long-Term Results

Proper care after rivet removal extends the life of your interior and future fasteners. This proactive approach minimizes wear and makes any subsequent work much easier. A little maintenance goes a long way in vehicle upkeep.

Post-Removal Cleaning and Care

Once rivets are out, take a moment to prepare the area for reinstallation. This ensures a solid fit and prevents future issues.

- Clean the Mounting Holes: Use compressed air or a small brush to remove dust, debris, and old plastic fragments from the panel holes. This allows the new rivet to seat fully.

- Inspect the Trim Panel: Check the plastic around the mounting holes for hairline cracks or stress marks. Small cracks can be stabilized with a drop of plastic-safe super glue.

- Lubricate if Necessary: For metal-on-plastic contact points, apply a tiny amount of silicone-based lubricant. This reduces friction during installation and future removal.

Preventing Future Rivet Damage

You can take simple steps to avoid premature rivet failure. This is especially useful for parts you plan to remove multiple times.

When installing new rivets, avoid over-tightening by pushing the pin too hard. The goal is a firm “click,” not to force the pin through the back of the rivet body. This preserves the fastener’s integrity.

Consider using a dedicated fastener for panels you access often, like for stereo or fuse box work. Screw-based trim clips or Velcro strips allow for repeated access without wearing out plastic rivet holes.

Storage Tip: Keep a small, labeled organizer in your garage with spare rivets sorted by size. Include a few universal repair washers. This saves a trip to the auto parts store mid-project.

When to Seek Professional Help

While most rivet removal is DIY-friendly, some situations warrant a professional touch. Knowing your limits protects your vehicle’s value.

If a rivet is located in an area with integrated electronics, airbag sensors, or complex wiring, professional disassembly may be safer. Also, if multiple mounting tabs are broken and require plastic welding, a specialist has the right tools for an invisible repair.

Troubleshooting Guide for Plastic Rivet Problems

Even with the best technique, you may encounter stubborn issues. This troubleshooting guide provides direct solutions to the most common problems. Quick diagnosis and the right fix will keep your project on track.

Solving Stuck and Broken Fasteners

When a rivet refuses to cooperate, don’t force it. These targeted methods can free even the most difficult fasteners.

- Spinning Center Pin: The pin turns but won’t pull. Use a flat tool to apply downward pressure on the rivet’s outer flange while simultaneously pulling the pin up with pliers.

- Sheared-Off Pin Head: If the pin head breaks, use a small drill bit (1/16″) to drill a shallow pilot hole into the pin stub. Insert a small screw extractor or a torx bit and pull.

- Stuck Rivet Body: The pin is out, but the body won’t pry free. Spray a small amount of penetrating lubricant like WD-40 around the base, wait, then try prying from alternating sides.

Repairing Damaged Mounting Holes

A stripped or enlarged hole won’t hold a new rivet securely. Fortunately, several effective repairs are possible without replacing the entire panel.

For a slightly enlarged hole, a trim clip repair washer or a larger diameter rivet is the simplest fix. For a cracked hole, apply a two-part plastic epoxy to the backside of the panel, let it cure, then drill a new pilot hole of the correct size.

| Problem Symptom | Root Cause | Effective Repair Method |

|---|---|---|

| New rivet pushes in too easily and feels loose | Mounting hole is worn or enlarged from previous removal. | Use a trim clip repair washer or fill the hole with epoxy and re-drill. |

| Trim panel won’t sit flush after rivet installation | Rivet is too long, bottoming out, or a hidden clip is misaligned. | Check rivet length, ensure all other clips are seated, and inspect for obstructions. |

| Rivet pin won’t “click” and seat fully | Debris in the rivet body, wrong rivet type, or damaged legs. | Clear debris, verify correct rivet, or discard and use a new fastener. |

Quick Fix: For a temporary hold on a stripped hole, wrap the shank of the rivet with a single layer of Teflon (plumber’s) tape. This can provide enough friction for a secure fit until a permanent repair is made.

Conclusion: Mastering Interior Plastic Rivet Removal

Removing interior plastic rivets cleanly is a simple skill with the right knowledge. You can now tackle this task without damaging your vehicle’s trim. The proper tools and technique make all the difference.

Remember to always remove the center pin first and use non-marring tools. This is the single most important step for success. Keep a variety of spare rivets on hand for replacements.

Gather your tools and practice on an inconspicuous rivet first. Apply these proven methods to your next stereo installation, wiring project, or trim repair with confidence.

You have the expertise to handle this common automotive task professionally. Your interior will look untouched when the job is done correctly.

Frequently Asked Questions about Removing Interior Plastic Rivets

What is the best tool to remove plastic rivets without scratching?

The best tool is a dedicated plastic trim removal kit with forked pry tools. These are made from nylon or coated metal to prevent scratches. The forked end slips under the rivet’s center pin perfectly.

Brands like CTA Tools or Lisle offer excellent kits. Avoid using standard screwdrivers or metal picks, as they will almost certainly mar your interior surfaces and leave visible damage.

How do you remove a plastic rivet when the center pin is broken off?

If the pin head shears off, you’ll need to extract the remaining stub. First, use a small drill bit (about 1/16″) to create a shallow pilot hole in the center of the broken pin.

Then, gently tap a small screw extractor or a torx bit into the hole. Use pliers to grip the bit and pull the pin straight out. Proceed carefully to avoid damaging the rivet body or panel.

Can you reuse interior plastic rivets after removal?

It is possible but not generally recommended. The plastic legs that expand and lock can become fatigued or slightly deformed during removal. A reused rivet may not hold as securely, leading to a loose panel or rattles.

For a professional, rattle-free result, always install new replacement rivets. They are inexpensive and ensure a tight, reliable fit that matches the factory installation.

What should you do if the plastic rivet mounting hole is stripped?

A stripped hole is a common issue. The simplest fix is to use a trim clip repair washer, which fits around the rivet shank to take up the extra space. Alternatively, you can use a slightly larger diameter rivet.

For a more permanent repair on the backside of the panel, apply a two-part plastic epoxy. Once cured, you can drill a new, correctly-sized hole in the reinforced area.

Why won’t my new plastic rivet click into place when installing?

If the pin won’t seat with a firm click, there is likely an obstruction. Check that the rivet body is fully inserted into the clean mounting hole. Also, ensure no debris is inside the rivet body itself.

The rivet may also be the wrong type or size for the hole, or its locking legs could be damaged. Try a different, new rivet from your kit to isolate the problem.

How do you remove plastic rivets from a headliner without tearing it?

Extreme caution is needed here. Use an extra-wide, flat plastic trim tool to distribute pressure over a larger area. Gently work the tool under the rivet’s edge, not the headliner fabric itself.

Apply slow, steady pressure and work around the rivet gradually. Supporting the headliner material with your other hand from behind can prevent sagging and stress that leads to tears.

What is the difference between a plastic rivet and a Christmas tree clip?

A plastic push rivet has two distinct parts: a body and a separate center pin that expands it. A Christmas tree clip is a one-piece fastener with barbed legs that grip the sides of the hole.

Removal differs: rivets require pin extraction first, while Christmas tree clips are removed by gripping the base with pliers and pulling straight out, or prying up the center post.

Is heat safe to use on stuck plastic interior rivets?

Yes, mild heat can be very effective. Use a hairdryer on a low or medium setting to gently warm the plastic rivet and surrounding area for 30-45 seconds. This makes the plastic more flexible and less brittle.

Never use a high-heat gun or open flame, as this can easily melt or warp the trim. The goal is to warm the plastic slightly, not to soften it completely.