Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Preventing scratches during trim removal requires the right tools, technique, and patience. This common DIY task can quickly damage your vehicle’s paint if done incorrectly. Our complete guide provides expert tips to keep your finish flawless.

Scratched paint is costly and frustrating, but it’s entirely avoidable. Using proven methods protects your investment and ensures a professional-looking result. You can achieve a clean removal without any damage.

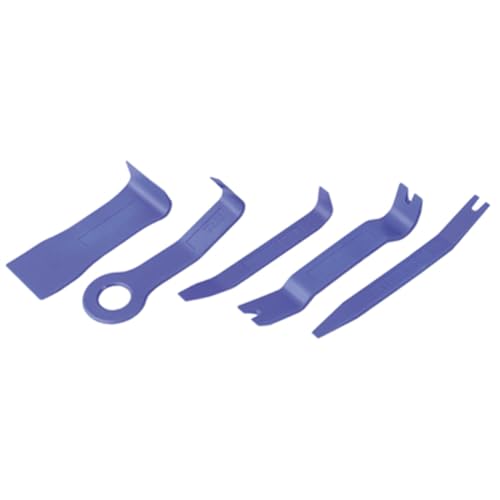

Best Tools for Scratch-Free Trim Removal

Steck Manufacturing 21720 Sure Grip Trim Removal Tool Kit – Best Overall Choice

The non-conductive, non-marring material is ideal for automotive interiors and exteriors. It’s the best option for a versatile, all-in-one solution.

- Auto & Truck Maintenance

- Country of manufacture: China

- Manufacturer: STECK

OTC 4489 Plastic Trim Tool Set – Best for Professional Use

OTC’s set features durable, molded plastic tools with precise, thin edges designed to slip behind trim seamlessly. The ergonomic handles provide excellent leverage and control. This set is highly recommended for frequent use and tackling stubborn clips without paint transfer.

- Tools are made of plastic to prevent damage to trim, moldings, alloy wheels…

- Can be used on trim fasteners and moldings inside, or outside the vehicle

- OTC 4489 Trim Fastener and Molding Removal Set

Lisle 35260 Plastic Fastener Remover – Best for Tight Spaces

The Lisle 35260 is a specialized, hook-style tool perfect for door panels and tight areas. Its unique forked end safely releases push-pin retainers and clips. This is the ideal tool for specific, hard-to-reach applications where standard pry tools are too bulky.

- Removes Plastic Hold-Down Fasteners.

- This tool quickly removes various types of plastic fasteners that hold on…

- The tool is equipped with a sliding urethane button for use when extra…

Essential Tools and Materials for Safe Trim Removal

Using the correct equipment is the first critical step in preventing paint scratches. The right tools create a barrier between metal and paint. Never use screwdrivers or metal tools for prying.

Non-Marring Pry Tools: Your First Line of Defense

Invest in a set of high-quality nylon or plastic trim removal tools. These are designed to flex without breaking and will not transfer metal particles. Their smooth edges distribute pressure evenly across the paint surface.

- Nylon Pry Tools: Flexible and durable, perfect for most interior and exterior trim pieces without leaving marks.

- Trim Removal Fork Tools: Specifically shaped to hook behind clips and pop them free cleanly, minimizing lateral movement.

- Soft-Grip Handles: Provide better control to prevent slips that can lead to sudden, damaging jabs against the panel.

Supporting Materials for a Flawless Process

The right tools are only half the battle. Supporting materials protect the paint during and after the removal process. They prepare the surface and manage the adhesive.

Painter’s tape is indispensable. Apply it along the paint edge adjacent to the trim before you start. This creates a protective bumper. It absorbs minor slips from your tools.

For adhesive residue, you need the correct cleaners. Use a dedicated automotive adhesive remover and plastic razor blades. This combination dissolves glue without the scratching risk of metal blades.

Key Takeaway: Never improvise with metal tools. A proper kit of nylon pry tools, painter’s tape, and plastic scrapers forms a complete scratch-prevention system.

Pre-Removal Preparation Checklist

Follow this simple checklist before making your first pry. Proper preparation drastically reduces the chance of error.

- Clean the Area: Wash and dry the trim and surrounding paint to remove abrasive dirt and grit.

- Apply Protective Tape: Run a strip of painter’s tape along the paint line next to the trim piece.

- Inspect Clip Locations: Identify where the retaining clips are (often behind trim) to apply force precisely.

- Gather All Tools: Have your pry tools, adhesive remover, and plastic scrapers within easy reach.

Step-by-Step Technique for Scratch-Free Removal

Mastering the correct technique is as important as having the right tools. This methodical approach minimizes risk at every stage. Patience and controlled force are your greatest allies.

Initial Prying and Clip Release

Start by gently inserting your nylon tool between the trim and painted panel. Work from an inconspicuous corner or seam. Use a slow, rocking motion to gradually increase pressure until the first clip releases.

- Locate Clip Points: Apply pressure directly behind known clip locations, not randomly along the trim’s length.

- Use a Rolling Motion: Rock the tool back and forth to “walk” it along, rather than forcing it in one spot.

- Listen for the Click: A clean, sharp pop indicates a clip has released properly. A cracking sound may mean you’re stressing the plastic.

Working Along the Trim Piece

Once the first clip is free, do not pull the trim away. Re-insert your tool a few inches further along and release the next clip. Work your way methodically down the entire piece, releasing each fastener in sequence.

For long trim pieces, use multiple tools as wedges. After releasing several clips, slide a second plastic tool into the gap to hold it open. This prevents clips from re-securing and reduces strain on the trim.

Pro Tip: If a section feels stuck, stop. Re-examine for hidden screws or secondary clips. Forcing it is the fastest way to cause a scratch or break the trim.

Dealing with Stubborn Adhesive and Clips

Some trim uses adhesive tape alongside clips. Apply steady, rearward tension on the trim while directing a hairdryer or heat gun on low at the adhesive line. The heat softens the tape for a cleaner release.

If a plastic clip breaks and remains in the body panel, extract it carefully. Use needle-nose pliers with taped jaws to grip the clip remnants. Twist and pull straight out to avoid damaging the panel hole.

| Problem | Safe Solution | Tool to Use |

|---|---|---|

| Stubborn Adhesive Tape | Apply gentle heat (under 200°F) | Hairdryer, Plastic Pry Tool |

| Broken Clip in Panel | Extract with twisting motion | Taped Needle-Nose Pliers |

| Extremely Tight Fit | Use a lubricant like soapy water on tool edge | Nylon Tool, Spray Bottle |

Common Mistakes and How to Avoid Them

Even with good intentions, simple errors can lead to costly scratches. Recognizing these common pitfalls is key to prevention. Learn from others’ mistakes to guarantee a perfect result.

Using Improper Tools and Excessive Force

The most frequent error is reaching for a screwdriver or metal putty knife. These tools concentrate force on a tiny, hard edge. They will dig into and gouge the paint immediately upon slipping.

- Metal Tools: Guarantee scratches and leave tiny metal fragments that can cause rust. Always use plastic or nylon.

- Prying at the Wrong Angle: Insert your tool parallel to the panel, not angled into it. Angling directs force toward the paint.

- Rushing the Process: Impatience leads to jerky, uncontrolled movements. Apply steady, increasing pressure until the clip yields.

Neglecting Preparation and Cleanup

Failing to prepare the work area invites abrasive contaminants into the process. Dirt on the panel or tool acts like sandpaper. Skipping adhesive cleanup can also cause re-installation damage.

Never pull trim away from the car before all clips are released. This bends the trim and over-stresses the remaining clips. The sudden release can cause the trim to whip back and strike the paint.

Critical Warning: Avoid using a heat gun on high setting near paint or plastic trim. Excessive heat can blister paint and warp or melt plastic components, causing irreversible damage.

Post-Removal Pitfalls

The risk of scratching isn’t over once the trim is off. Laying the removed trim on the painted surface can cause scuffs. Placing dirty tools on the car’s hood or roof is another common oversight.

| Mistake | Consequence | Prevention Tip |

|---|---|---|

| Using a Metal Blade for Adhesive | Deep, straight-line scratches in clear coat | Use plastic razor blades only |

| Not Taping Adjacent Paint | Tool slips cause instant paint chips | Always apply painter’s tape as a buffer |

| Storing Tools on Car Paint | Fine scratches from grit on tool handles | Use a clean rag or tray as a work surface |

Finally, clean all adhesive residue completely before reinstalling trim. Leftover glue creates an uneven surface. This can prevent proper seating and put pressure on the paint edge.

Advanced Tips for Specific Trim Types and Vehicles

Different materials and vehicle ages require tailored approaches. Modern cars often use more complex fastening systems. Understanding these variations elevates your technique from good to expert.

Handling Delicate Materials and Modern Vehicles

Newer vehicles frequently feature chrome-accented, gloss black, or fragile plastic trim. These materials scratch and mar more easily than standard textured plastic. They demand an even gentler touch and more protection.

- Gloss Black Plastic: Use a microfiber-wrapped pry tool for initial insertion. Even nylon can leave subtle marks on this soft finish.

- Chrome Trim: Tape over the entire visible chrome surface before starting. The thin plating is easily chipped by a wayward tool.

- Weatherstripping & Seals: These are often glued. Use a steady pull combined with a dedicated adhesive release spray, not brute force.

Dealing with Old, Brittle, or Sun-Damaged Trim

On classic or older cars, plastic becomes brittle with age and UV exposure. The primary risk shifts from scratching paint to cracking the trim itself. A broken trim piece is often harder to replace than fixing a scratch.

Warm the entire trim piece gently with a hairdryer before starting. This restores slight flexibility to the old plastic. Work slowly and listen carefully for any cracking sounds, stopping immediately if heard.

Expert Insight: For vintage cars, sourcing intact original trim is difficult and expensive. Preserving the trim is sometimes more critical than preserving the paint during removal.

Vehicle-Specific Considerations

Always consult a vehicle-specific repair manual or online forum before starting. Manufacturers use unique clip designs and hidden fasteners. Knowing their locations is half the battle.

| Vehicle Type | Common Challenge | Specialized Technique |

|---|---|---|

| German Luxury (BMW, Mercedes) | Complex hidden screws under caps | Use a panel popper to remove access plugs first |

| Modern Trucks & SUVs | Long, rigid rocker panel trim | Use two people to support length during removal |

| Japanese Economy Cars | Very tight clip spacing | Use the thinnest tool in your kit and work incrementally |

For trim secured with double-sided automotive molding tape, use a dedicated “trim removal wire” or “fishing line” sawing technique. This cuts through the adhesive cleanly from behind without prying at all.

Post-Removal Care and Reinstallation Best Practices

Properly caring for the trim and paint after removal ensures a perfect finish. This phase is critical for preventing future issues and scratches. A clean reinstallation protects your work.

Cleaning and Preparing Surfaces for Reassembly

Once the trim is removed, thoroughly clean both the vehicle’s panel and the back of the trim piece. Remove all old adhesive, grease, and debris. Any leftover grit will act as an abrasive during reinstallation.

- Panel Surface: Use automotive adhesive remover and a plastic razor blade to scrape residue. Follow with isopropyl alcohol for a final, grease-free wipe.

- Trim Backing: Clean old foam tape or glue from the trim. Inspect plastic clips for damage and replace any that are cracked or bent.

- Dry Fit Test: Before applying new tape, test-fit the trim to ensure all clips align perfectly with their holes. Misalignment forces installation.

Applying New Adhesive and Securing Trim

For trim using tape, apply new 3M Automotive Attachment Tape or equivalent. Cut strips to match the original pattern. Leave the red liner on until you are ready for final placement.

When reinstalling, start by engaging the clips at one end. Do not press the adhesive side down yet. Once all clips are started along the length, apply firm, even pressure along the entire trim piece to seat the tape.

Pro Tip: In cold weather, warm the new adhesive tape and the vehicle’s panel with a hairdryer before installation. This greatly improves initial bond strength and final hold.

Final Inspection and Paint Protection

After reinstallation, perform a meticulous inspection. Run your finger along the seam between the trim and paint. It should be even and flush with no gaps or raised edges.

| Step | Action | Goal |

|---|---|---|

| 1. Visual Check | Look for even gaps and flush mounting | Ensure proper alignment |

| 2. Tactile Check | Feel for raised edges or loose sections | Confirm full adhesive contact |

| 3. Functional Check | Gently try to wiggle the trim | Verify all clips are fully seated |

Finally, clean the surrounding paint area to remove fingerprints or oils. Consider applying a protective spray wax or sealant to the paint. This adds a protective layer for future maintenance.

What to Do If You Accidentally Scratch the Paint

Despite best efforts, minor scratches can sometimes occur. Knowing how to assess and repair them immediately is crucial. Quick action can prevent the damage from worsening or requiring a full repaint.

Assessing the Scratch Depth

First, determine if the scratch is superficial or deep. Run your fingernail gently across the mark. If your nail catches in the groove, the scratch is through the clear coat and likely into the color layer.

- Clear Coat Scratch: Only affects the top protective layer. Your nail will not catch. These are often repairable by polishing.

- Base Coat Scratch: Your nail catches slightly. The color layer is damaged, requiring touch-up paint after cleaning.

- Primer/Bare Metal Scratch: Nail catches deeply, revealing a dark grey or silvery line. This demands immediate repair to prevent rust.

Immediate Repair Steps for Minor Scratches

For clear coat scratches, start with the least aggressive method. Clean the area thoroughly with car wash soap and water. Dry it completely with a microfiber towel.

Apply a fine automotive polishing compound to a clean microfiber pad. Rub the compound over the scratch using light pressure in a back-and-forth motion. The goal is to level the clear coat, not remove it entirely.

Warning: Do not use heavy rubbing compound or a power polisher unless you are experienced. You can easily burn through the thin clear coat, making the damage far worse.

When to Use Touch-Up Paint or Seek Professional Help

If polishing doesn’t remove the scratch, it has reached the color layer. For small, isolated scratches, a factory-matched touch-up paint pen is the next step.

| Scratch Severity | Recommended Action | Expected Outcome |

|---|---|---|

| Light Clear Coat Marring | Hand polish with fine compound | Scratch becomes invisible |

| Visible Color Layer Scratch | Clean, apply touch-up paint in layers, polish blend | Scratch filled, visible upon close inspection |

| Deep Gouge to Metal | Professional repair or panel repaint | Fully restored finish |

For long, deep, or numerous scratches, consult a professional detailer or body shop. Their expertise and tools, like paint depth gauges and professional polishers, provide a safer, superior result than aggressive DIY attempts.

Proactive Maintenance and Long-Term Protection Strategies

Preventing scratches is an ongoing process, not a one-time task. Implementing smart maintenance habits protects your vehicle’s finish for years. These strategies make future trim work safer and easier.

Regular Inspection and Care of Trim Seals

Periodically inspect the condition of your vehicle’s trim and the paint line beneath it. Look for dirt buildup, deteriorating adhesive, or trim that is starting to lift. Catching issues early prevents forced, risky removal later.

- Clean the Seams: Use a soft detailing brush and soapy water to clean where trim meets paint. This removes abrasive grit that can cause micro-scratches.

- Check for Lift: Gently press along trim edges. If a section moves, the adhesive is failing. Plan a controlled reattachment before it falls off.

- Protect with Sealant: Apply a quality paint sealant or ceramic coating to the paint adjacent to trim. This creates a harder, more scratch-resistant surface.

Creating a Dedicated Trim Work Kit

Assemble a permanent kit with all your scratch-prevention tools. Store it together so you’re never tempted to improvise. This ensures you’re always prepared for safe removal.

Your kit should include nylon tools, painter’s tape, plastic razor blades, adhesive remover, and isopropyl alcohol. Add a small LED work light for clear visibility of clips and seams. Good lighting is a critical safety tool.

Smart Investment: Consider a paint depth gauge. This tool measures your clear coat thickness, telling you how much material you can safely polish if a scratch does occur.

Environmental and Workspace Best Practices

Your working environment significantly impacts risk. Always choose a clean, shaded, and well-lit area. Direct sun heats panels and makes plastics more pliable and adhesive stickier, complicating removal.

| Condition | Risk Factor | Optimal Solution |

|---|---|---|

| Dirty/Gritty Workspace | High risk of embedded abrasives | Work in a clean garage or on a clean driveway |

| Hot, Sunny Weather | Soft paint, gummy adhesive | Work in early morning or shaded area |

| Cold Weather | Brittle plastic trim | Warm trim with hairdryer before starting |

Finally, keep a log of any trim you remove and the clip types used. This reference is invaluable for future projects on the same vehicle. Knowledge is the ultimate form of protection.

Conclusion: Mastering Scratch-Free Trim Removal

Preventing scratches during trim removal is entirely achievable with the right knowledge. Using proper tools and a patient technique protects your vehicle’s finish. This saves you from costly paint repairs and preserves your car’s value.

The key takeaway is to never use metal tools and always apply protective tape. Methodical preparation and controlled force are your greatest allies. Follow the step-by-step process outlined in this guide for guaranteed success.

Assemble your scratch-prevention kit today and tackle your next project with confidence. Share this guide with fellow DIY enthusiasts to help them protect their vehicles too. Your flawless finish is just a careful removal away.

With these pro tips, you can maintain your car’s appearance like a professional. Enjoy the satisfaction of a job done right, without any costly damage.

Frequently Asked Questions about Preventing Scratches During Trim Removal

What is the best tool to remove car trim without scratching?

The best tools are professional-grade nylon or plastic trim removal kits. These non-marring tools flex to avoid paint damage. Brands like Steck Manufacturing or OTC offer sets with multiple shapes for different clips.

These plastic tools distribute pressure evenly across the paint surface. They are far superior to improvised metal tools like screwdrivers, which concentrate force and guarantee scratches.

How do you remove glued-on trim without damaging paint?

For adhesive-backed trim, use a combination of gentle heat and a specialized tool. Apply low heat from a hairdryer to soften the adhesive tape along the seam. This makes it more pliable for removal.

Simultaneously, use a plastic trim tool or a dedicated “trim removal wire” to slowly work behind the trim. The wire saws through the adhesive cleanly from behind without any prying force on the paint.

Can you use a heat gun for trim removal safely?

Yes, but only with extreme caution and on a low setting. High heat can blister paint and melt plastic trim in seconds. Always keep the heat gun moving and test on an inconspicuous area first.

A hairdryer is often a safer, more controllable option for DIYers. It provides enough heat to soften adhesives without the high-temperature risks associated with a professional heat gun.

What should I do if a plastic clip breaks during removal?

If a clip breaks, stop and extract the remaining piece from the body panel carefully. Use needle-nose pliers with the jaws wrapped in electrical tape to grip the fragment. This prevents scratching the panel hole.

Twist and pull the broken clip straight out. Never leave broken pieces in the panel, as they can prevent the new clip from seating properly or cause rattles.

How do you remove old, brittle trim without cracking it?

Warming the entire trim piece is crucial for old plastic. Use a hairdryer on a medium setting to gently heat the trim for several minutes before starting. This restores some flexibility to the sun-damaged material.

Work even slower than usual and apply steady, rearward pressure rather than a prying motion. Listen carefully for any cracking sounds and stop immediately if you hear them.

What is the best way to clean adhesive residue off paint?

Use a dedicated automotive adhesive remover or a citrus-based degreaser. Spray it on the residue and let it soak for the time specified on the label. This dissolves the glue without harming the clear coat.

Always scrape the softened residue with a plastic razor blade, holding it at a shallow angle. Follow up with isopropyl alcohol to remove any final film and prepare the surface for new tape.

Is painter’s tape really necessary for trim removal?

Yes, painter’s tape is a critical, low-cost insurance policy. Applying a strip along the paint edge adjacent to the trim creates a protective bumper. It absorbs minor slips and prevents direct tool-to-paint contact.

This simple step can mean the difference between a harmless tape mark and a deep paint chip. It is especially important when working near delicate finishes like gloss black or chrome accents.

How long should new adhesive tape cure before driving?

For the strongest bond, allow new 3M VHB tape to cure for 24-72 hours before exposing the vehicle to car washes or high speeds. The initial bond is strong, but full strength develops over time.

Park the vehicle in a warm garage if possible, as heat aids the curing process. Avoid putting stress on the trim or washing the car during this initial curing period for best results.