Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Yes, you likely need a hardwire kit for a dash cam—if you want professional-grade reliability, parking mode functionality, and a clutter-free setup. Many drivers assume plugging into the cigarette lighter is enough, but this limits critical features and leaves wires dangling.

Modern dash cams demand more: seamless power, 24/7 surveillance, and protection against battery drain. Imagine capturing a hit-and-run while parked—only possible with proper hardwiring.

Best Hardwire Kits for Dash Cams

VIOFO HK3 ACC Hardwire Kit

Ideal for VIOFO dash cams (like the A129 Pro), this kit features a low-voltage cutoff to protect your car battery, adjustable voltage settings (11.8V–12.4V), and a compact design. It ensures seamless parking mode activation without draining your battery—perfect for 24/7 surveillance.

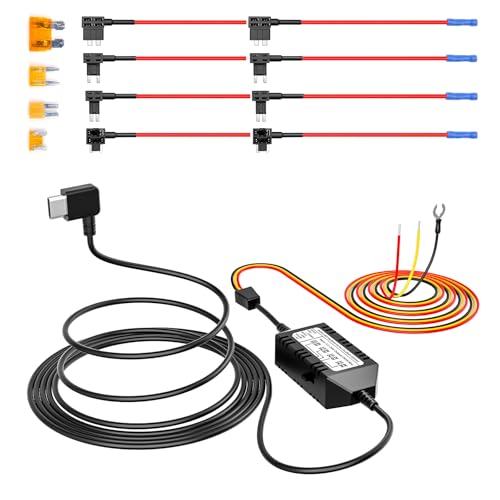

- 【24 Hours Parking Surveillance】When the engine is off, HK4 hardwire kit…

- 【Low Voltage Protection】HK4 hardwire lets you set a voltage cut-off…

- 【Automatically switch parking mode】With ACC detection, the dash cam…

BlackVue Power Magic Ultra Battery Discharge Prevention

Designed for BlackVue models (DR750X, DR970X), this professional-grade kit includes a built-in fuse and voltage monitor. It supports extended parking mode with customizable cutoffs (12.0V–12.4V) and works in extreme temperatures (-20°C to 70°C), making it reliable for all climates.

- Power your dashcam in Parking Mode.

- Protect your vehicle’s battery.

- Check the battery’s status wirelessly with the BlackVue app

Garmin Constant Power Cable

Compatible with Garmin dash cams (Mini 2, 67W), this plug-and-play kit offers automatic power switching between driving/parking modes. Its low-profile fuse taps blend into your vehicle’s wiring, while the 12V cutoff prevents battery drain—great for hassle-free, discreet installations.

- Product Type :Gps Or Navigation System

- Package Dimensions :2.756″ L X1.142″ W X5.512″ H

- Country Of Origin :Taiwan

Why a Hardwire Kit Is Essential for Your Dash Cam

While many drivers rely on their dash cam’s cigarette lighter power cable, this approach has critical limitations. A hardwire kit unlocks professional-grade functionality by connecting directly to your vehicle’s fuse box. Here’s why this matters:

1. Enables Parking Mode for 24/7 Protection

Without a hardwire kit, your dash cam shuts off when you turn the ignition off—leaving your vehicle vulnerable. Hardwiring powers the camera continuously, activating motion detection or time-lapse recording while parked. For example, if someone hits your car in a parking lot, the camera will capture the incident even if you’re not inside.

2. Prevents Battery Drain with Voltage Monitoring

Quality hardwire kits (like the VIOFO HK3) include a low-voltage cutoff (typically adjustable between 11.8V–12.4V). This automatically disconnects power when your car battery drops to a safe threshold, preventing a dead battery. Unlike USB power banks, which require manual charging, hardwiring is a “set it and forget it” solution.

3. Eliminates Clutter with a Clean Installation

Dangling power cables obstruct your view and invite tampering. Hardwiring routes wires discreetly along headliners and A-pillars, terminating at the fuse box. Professional installers often use add-a-circuit fuse taps to integrate seamlessly with existing electrical systems—no visible wires or bulky adapters.

Common Misconceptions Debunked

- “It’s too complicated.” Most kits include step-by-step guides, and basic tools (fuse pullers, trim tools) simplify DIY installation.

- “It voids my warranty.” Proper installation using fuse taps doesn’t alter factory wiring, preserving your vehicle’s warranty.

- “The cigarette lighter is enough.” This only works while driving and lacks parking mode or voltage protection.

Real-World Scenario: A Tesla owner using a BlackVue DR970X with a Power Magic Pro kit recorded a break-in overnight. The camera’s parking mode activated via hardwiring, providing crucial evidence to police—something impossible with a standard power cable.

For drivers serious about security, hardwiring isn’t optional. It transforms your dash cam from a driving recorder to a round-the-clock sentinel.

How to Choose the Right Hardwire Kit for Your Dash Cam

Selecting the optimal hardwire kit requires understanding your dash cam’s power needs and your vehicle’s electrical system. Here’s a detailed breakdown of key considerations:

1. Compatibility: Matching Your Dash Cam Model

Not all hardwire kits work universally. For example:

- Brand-specific kits (like BlackVue Power Magic) ensure seamless integration with parking mode features

- Universal kits require verifying connector types (Mini-USB vs. Micro-USB) and voltage input (typically 5V/12V)

Pro Tip: Check your dash cam’s manual for “hardwire-ready” specifications—some models (like Thinkware U1000) require proprietary kits for full functionality.

2. Voltage Protection: Safeguarding Your Battery

The best kits offer adjustable voltage cutoffs with these thresholds:

- 12.4V (recommended for daily drivers)

- 12.0V (for occasional use vehicles)

- 11.8V (emergency minimum, riskier for battery health)

Example: A Honda Civic owner using the VIOFO HK3 set at 12.2V could record parking footage for 48 hours without jump-start issues.

3. Installation Complexity: DIY vs. Professional

Key installation factors include:

- Fuse box location (German cars often hide them under glove compartments)

- Add-a-circuit fuse tap size (Mini vs. Low-profile blade fuses)

- Wire routing challenges (modern vehicles with curtain airbags require special tools)

Real-World Solution: A Ford F-150 owner solved ground connection issues by sanding paint off the chassis contact point—demonstrating why understanding basic automotive electrical principles matters.

For hybrid/electric vehicles, consult your dealer—some manufacturers restrict fuse box access to prevent warranty issues. In these cases, OBD-II power adapters (like Owl Cam’s solution) may be better alternatives.

Advanced Hardwiring Techniques and Professional Installation Tips

Mastering dash cam hardwiring requires understanding both electrical principles and vehicle-specific considerations. These professional techniques ensure optimal performance while avoiding common pitfalls.

1. Electrical System Analysis for Safe Installation

Modern vehicles use complex electrical architectures that demand careful planning:

| Vehicle Type | Key Consideration | Recommended Solution |

|---|---|---|

| Standard ICE Vehicles | 12V battery system with 40-100Ah capacity | Standard hardwire kit with 12.2V cutoff |

| Hybrid/Electric Vehicles | High-voltage systems with auxiliary 12V battery | OBD-II power adapter or manufacturer-approved kit |

| Luxury Vehicles | CAN bus systems with sensitive electronics | Professional installation with fuse tap isolators |

2. Professional-Grade Wiring Methods

Advanced installers recommend these techniques:

- Fuse Selection: Always tap into “switched” (ignition-controlled) circuits for the main power and “constant” circuits for parking mode

- Wire Routing: Use nylon trim tools to tuck wires behind airbag-equipped pillars without interfering with safety systems

- Grounding: Locate factory ground points or create new ones by sanding paint off chassis metal (torque to 8-10 Nm)

3. Troubleshooting Common Issues

Even proper installations can encounter problems:

- Battery Drain: If occurring despite cutoff settings, test parasitic draw with multimeter (should be <50mA when vehicle sleeps)

- Parking Mode Failure: Verify constant power fuse tap has 12V when ignition off using circuit tester

- Video Corruption: Often caused by voltage fluctuations – add a capacitor (0.5-1F) near dash cam power input

Expert Insight: BMW and Mercedes vehicles often require “fuse wake-up” procedures after installation – disconnecting the negative battery terminal for 15 minutes resets the electrical system and prevents error codes.

For vehicles with start-stop technology, consider a dash cam battery pack (like Cellink Neo) to maintain consistent power during engine restarts, which can cause voltage drops below hardwire kit cutoffs.

Optimizing Dash Cam Performance with Proper Hardwiring

Proper hardwiring goes beyond basic installation – it’s about maximizing your dash cam’s capabilities while ensuring vehicle safety. These professional techniques will help you achieve optimal results.

1. Power Management Strategies for Different Use Cases

The ideal setup varies significantly based on your driving patterns:

- Urban Commuters: Set voltage cutoff to 12.4V for short parking periods and frequent engine starts

- Weekend Vehicles: Use 12.0V cutoff with time-lapse mode (1fps) to extend recording duration

- Ride-share Drivers: Combine hardwiring with supercapacitors for continuous operation during 12+ hour shifts

Case Study: A New York City taxi driver using the BlackVue DR750X with Power Magic Pro maintained 72 hours of parking surveillance by setting the cutoff to 12.2V and using 5fps time-lapse mode.

2. Advanced Configuration for Extreme Conditions

Special environments demand tailored solutions:

- Cold Climates: Add 0.2V to standard cutoff settings (batteries discharge faster in cold)

- Hot Climates: Use thermal-resistant wiring (105°C rated) and avoid direct sun exposure

- Off-road Use: Install vibration-dampening mounts and waterproof fuse tap enclosures

3. Professional Maintenance and Monitoring

Maintaining peak performance requires regular checks:

| Maintenance Task | Frequency | Tools Needed |

|---|---|---|

| Fuse connection inspection | Every 6 months | Fuse puller, contact cleaner |

| Voltage cutoff verification | Seasonally | Multimeter, test light |

| Ground point corrosion check | Annually | Wire brush, dielectric grease |

Pro Tip: Modern dash cams with Wi-Fi (like Thinkware Q800 Pro) allow real-time voltage monitoring through smartphone apps, eliminating guesswork about power status.

For commercial fleets, consider professional-grade solutions like the Lytx DriveCam system, which includes vehicle integration modules that communicate directly with the CAN bus for enhanced power management and diagnostic capabilities.

Future-Proofing Your Dash Cam Hardwiring Setup

As vehicle technology evolves, so do the requirements for effective dash cam integration. This section explores how to create a system that remains functional through technological changes and vehicle upgrades.

1. Emerging Vehicle Technologies and Their Impact

Modern automotive advancements present new challenges for hardwiring:

| Technology | Hardwiring Challenge | Solution |

|---|---|---|

| 48V Mild Hybrid Systems | Voltage fluctuations during auto start-stop | Dual-voltage hardwire kits (12V/48V compatible) |

| Over-the-Air Updates | Power interruptions during software updates | Smart power managers with update detection |

| Advanced Driver Assistance Systems (ADAS) | Camera placement conflicts | Low-profile wiring with ADAS-calibrated mounts |

2. The Shift Toward Integrated Power Solutions

Industry trends are moving beyond traditional hardwiring:

- OBD-II Power Adapters: Plug-and-play solutions that monitor CAN bus data for smarter power management

- AI-Powered Energy Management: New systems like Garmin’s Smart Cable learn driving patterns to optimize battery usage

- Vehicle-Specific Harnesses: Manufacturer-approved adapters that plug into factory wiring points without splicing

3. Long-Term Cost Analysis

Understanding the true value of proper hardwiring:

- Upfront Costs: $20-$150 for quality kits vs. potential $500+ insurance deductible for unrecorded incidents

- Battery Longevity: Proper voltage cutoff can extend battery life by 2-3 years compared to parasitic drain

- Resale Value: Professionally installed systems increase vehicle appeal and can be transferred to new owners

Safety Consideration: The National Highway Traffic Safety Administration (NHTSA) now recommends dash cams as standard safety equipment, with proper hardwiring being critical for reliable operation during accidents when the ignition may be off.

Looking ahead, expect to see more vehicle manufacturers offering factory-installed dash cam provisions with dedicated power circuits, following Tesla’s lead with their built-in Sentry Mode system. Until then, proper aftermarket hardwiring remains the gold standard for reliable operation.

Professional Installation Techniques for Flawless Hardwiring

Mastering the physical installation process is just as critical as selecting the right components. These professional techniques ensure reliable operation while maintaining your vehicle’s integrity.

1. Vehicle-Specific Wiring Strategies

Different vehicle architectures demand tailored approaches:

- German Luxury Vehicles: Require fuse tap orientation checks (reverse polarity common in BMW/Mercedes fuse boxes)

- Japanese Kei Cars: Need ultra-compact wiring solutions due to minimal spare space

- American Trucks: Benefit from waterproof connections for off-road conditions

Real-World Example: A 2023 Ford F-150 installation requires special attention to the BCM (Body Control Module) fuse box, where incorrect tapping can trigger false alarm messages.

2. Advanced Wire Routing Techniques

Professional installers use these methods for invisible installations:

- A-Pillar Routing: Always verify airbag deployment paths using factory service manuals

- Headliner Tucking: Use nylon trim tools at 45-degree angles to avoid creasing fabric

- Firewall Penetration: Only use existing grommets and seal with butyl rubber

3. Precision Electrical Connections

Proper termination prevents future issues:

| Connection Type | Best Practice | Tool Required |

|---|---|---|

| Fuse Tap | Load side towards original fuse | Mini fuse puller |

| Ground Point | Sand to bare metal + dielectric grease | 10mm socket |

| Wire Splices | Heat shrink solder sleeves | Butane torch |

Pro Tip: For vehicles with aluminum bodies (like Land Rover), always use stainless steel screws for ground connections and apply anti-corrosion compound to prevent galvanic corrosion.

Modern vehicles with active noise cancellation systems require special consideration – routing dash cam wires too close to microphone arrays can introduce interference. Maintain at least 6″ separation from any ANC components.

System Integration and Long-Term Maintenance Strategies

A professional-grade dash cam installation requires ongoing attention to system interactions and preventative maintenance. This final section provides a master checklist for ensuring years of reliable operation.

1. Comprehensive Vehicle System Integration

Modern dash cams must coexist with numerous vehicle systems:

| Vehicle System | Integration Consideration | Testing Protocol |

|---|---|---|

| CAN Bus Network | Verify no interference with diagnostic communications | OBD-II scan for error codes post-installation |

| Security System | Ensure parking mode doesn’t trigger false alarms | Test with armed system during motion detection |

| Infotainment | Check for Bluetooth/WiFi interference | Simultaneous streaming test |

2. Advanced Performance Optimization

Maximize your system’s capabilities through these techniques:

- Power Cycling: Monthly full discharge/recharge maintains capacitor health

- Firmware Updates: Schedule quarterly checks for voltage management improvements

- Lens Calibration: Annual alignment checks ensure proper field of view coverage

3. Professional Maintenance Schedule

Implement this comprehensive maintenance routine:

- Monthly: Inspect fuse connections for corrosion (use contact cleaner if needed)

- Quarterly: Test voltage cutoff accuracy with variable power supply

- Biannually: Verify ground connection integrity (target 0.2Ω resistance max)

- Annually: Complete wire harness inspection for chafing or rodent damage

Critical Failure Prevention: Installations in extreme climates require additional measures – in desert environments, add thermal shielding to wiring near exhaust components, while Arctic installations need battery warmers to maintain proper voltage cutoff functionality.

For commercial fleets, implement a digital twin system that logs all hardwiring parameters and alerts managers to deviations from baseline performance, enabling predictive maintenance before failures occur.

Conclusion

As we’ve explored, a hardwire kit is essential for unlocking your dash cam’s full potential – enabling parking mode, preventing battery drain, and achieving professional-grade reliability. From selecting the right voltage cutoff to mastering vehicle-specific installation techniques, proper hardwiring transforms your dash cam from a simple recorder to a comprehensive security system. Whether you’re a daily commuter or commercial operator, investing in quality components and proper installation pays dividends in protection and peace of mind. Take action today: Assess your vehicle’s needs, choose a compatible kit from our recommended options, and either DIY with our professional tips or consult a certified installer. Your future self will thank you when critical footage is there when you need it most.

Frequently Asked Questions About Dash Cam Hardwire Kits

What exactly does a hardwire kit do for my dash cam?

A hardwire kit provides direct connection to your vehicle’s fuse box, enabling three key benefits: continuous power for parking mode, clean installation without visible wires, and voltage protection to prevent battery drain. Unlike cigarette lighter adapters, it taps into your car’s electrical system using fuse taps, with built-in circuitry to automatically shut off when battery voltage drops below your preset threshold (typically 11.8V-12.4V).

Can I install a hardwire kit myself or need a professional?

Many tech-savvy owners can DIY with basic tools (fuse puller, trim tools, multimeter), but consider professional installation if: your vehicle has complex electronics (German luxury cars), the fuse box is hard to access (some hybrids), or you’re uncomfortable working with automotive wiring. Average installation time is 1-2 hours for first-timers versus 30 minutes for professionals.

Will hardwiring void my vehicle’s warranty?

Proper installation using add-a-circuit fuse taps won’t void warranties as it doesn’t modify factory wiring. However, dealerships may blame aftermarket equipment for electrical issues. Protect yourself by: using manufacturer-approved kits, keeping installation receipts, and removing the system before warranty service. Magnuson-Moss Warranty Act protects consumers against blanket voiding of warranties.

How do I choose the right voltage cutoff setting?

Select based on your battery type and climate: 12.4V for AGM batteries in cold climates, 12.2V for standard lead-acid in temperate zones, or 11.8V for emergency use only. Test with a multimeter – your resting voltage after overnight parking should be 0.2V above your cutoff. For example, if your car measures 12.3V in the morning, set cutoff to 12.1V.

Why does my hardwired dash cam keep turning off randomly?

Common causes include: loose fuse tap connections (reseat all fuses), incorrect ground point (test with multimeter – should show <0.5Ω resistance), or voltage fluctuations from failing alternator. For modern cars with start-stop systems, consider adding a dash cam battery pack to maintain power during engine restarts when voltage temporarily drops.

What’s the difference between $20 and $100 hardwire kits?

Premium kits (BlackVue Power Magic Pro) offer: adjustable voltage cutoffs, built-in fuses, temperature-resistant wiring, and parking mode timers. Budget kits often lack precise voltage monitoring, risking battery drain. For example, a $20 kit might shut off at 11.5V (too low), while a $100 kit maintains accuracy within 0.1V even in extreme temperatures.

Can I use one hardwire kit for multiple dash cams?

Only with proper load calculation. Most kits support 2-3A max (enough for 1-2 cameras). For dual-channel systems (front/rear), verify total power draw doesn’t exceed kit capacity. Example: Thinkware U1000 dual cam draws 1.8A – use a 3A kit like the Thinkware HWK. Never daisy-chain multiple cameras on one circuit without professional assessment.

How often should I check my hardwired dash cam system?

Perform quarterly maintenance: inspect fuse connections for corrosion, verify ground point integrity, and test voltage cutoff accuracy. Before long trips or extreme weather, conduct additional checks. Modern systems with app connectivity (like BlackVue) can self-monitor and alert you to power issues, reducing manual checks needed.