Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

No, air compressor pressure switches are not universal. They are critical components with specific requirements. Choosing the wrong one can damage your compressor or create a safety hazard.

Best Pressure Switches for Air Compressor Replacement

Square D 9013FHG12J52M1X Pressure Switch

This is a highly reliable industrial-grade switch ideal for heavy-duty workshop compressors. It features a 30-50 PSI adjustable range and a manual ON/OFF lever. Its durable metal construction and UL/CSA certification make it a top choice for consistent performance and safety on 120V applications.

- 9013FHG12J52M1X

- 1 Port pressure switch 95-125

- Pressure switch W/ Unloader & ON/OFF LEVER

XIAOWEI 321020000F Pressure Switch

Perfect for standard garage air compressors, this model offers straightforward installation and proven durability. It comes pre-set to the common 30-50 PSI cut-in/cut-out range. Its compact design and universal 1/4″ NPT port make it a direct replacement for many popular OEM units without modification.

- Replace Part Number : 321020000F,MDR21-EA/11,MDR21

- Cuts in at 95psi – Cuts out at 125psi

- Differential: 30 to 40 psi

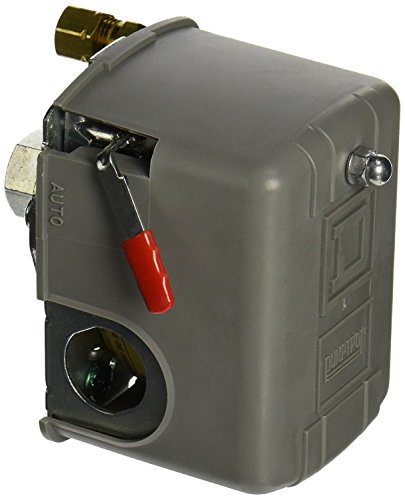

Condor MDR EA/11 Adjustable Pressure Switch

For users needing customizable pressure control, the Condor MDR series excels. It allows you to precisely adjust both the cut-in and cut-out points across a wide range.

This flexibility makes it the best option for specialized applications or compressors where the factory setting is no longer optimal.

- DETAILS ABOUT MDR21-EA/11 CONDOR PRESSURE SWITCH 4 PORT W/ UNLOADER &…

- CAP# 0101SP CONDOR PART# MDR21-EA11 ROLAIR CONDOR PRESSURE SWITCH W/…

- Features: 3 and 5 HP 200 PSI maximum Improved unloader valve design Several…

Air Compressor Pressure Switch Compatibility

Finding a universal pressure switch is impossible due to several critical specifications. Your compressor’s electrical and mechanical design dictates the exact replacement part needed. Ignoring these factors risks equipment failure or unsafe operation.

Key Electrical Compatibility Factors

The electrical rating is the most important safety consideration. A mismatch can cause the switch to fail catastrophically.

- Voltage (V) & Phase: Match exactly (e.g., 120V/1-Phase or 240V/1-Phase). Using a 120V switch on a 240V circuit will destroy it.

- Horsepower (HP) or Amperage (A) Rating: The switch must handle the motor’s starting current. A switch rated lower than your motor will overheat and fail.

- Terminal Type: Switches have different terminal configurations (screw, blade, lead wires). Ensure the new switch’s terminals match your compressor’s wiring setup.

Critical Mechanical Specifications

Physical connections and pressure settings must align for the system to function.

- Pressure Range (PSI): This defines the cut-in (start) and cut-out (stop) points. Common ranges are 30-50, 40-60, or 90-120 PSI. An adjustable switch must cover your compressor’s required range.

- Port Thread Size & Type: The fitting that connects to the tank is usually NPT (National Pipe Taper). Common sizes are 1/4″ or 3/8″ NPT. The thread must match exactly to prevent air leaks.

- Unloader Valve: Most switches include an unloader valve to release pressure from the pump head after shutdown. Verify if your system uses one and that the new switch has this feature if required.

Key Takeaway: Compatibility hinges on four exact matches: Voltage, Horsepower/Amperage, Pressure Range, and Port Thread. Always check your old switch’s specifications or your compressor’s manual before purchasing a replacement.

How to Choose the Correct Replacement Pressure Switch

Selecting the right switch requires a methodical approach. You must identify your compressor’s exact needs before shopping. This process ensures a safe, functional, and long-lasting replacement.

Step-by-Step Selection Guide

Follow these steps to guarantee compatibility and avoid costly mistakes.

- Identify Your Old Switch: Locate the manufacturer’s label on your old pressure switch. Write down all visible numbers, including model, voltage, HP, and PSI range.

- Match Electrical Specifications: Voltage and HP/amperage are non-negotiable. If the label is missing, refer to your air compressor’s manual or nameplate for the motor specifications.

- Verify Mechanical Fit: Check the port thread size by attempting to thread a known fitting. Also, note if your old switch has an unloader valve line or is a simple pressure switch.

- Decide on Adjustability: Fixed-range switches are simpler and cheaper. Adjustable switches offer future flexibility if your air tool needs change.

Fixed vs. Adjustable Pressure Switches

Understanding this key difference helps you choose the right type for your application.

| Feature | Fixed/Range Switch | Adjustable Switch |

|---|---|---|

| Pressure Setting | Factory pre-set (e.g., 30-50 PSI) | User-adjustable within a range |

| Best For | Direct OEM replacement, standard uses | Custom applications, changing needs |

| Complexity & Cost | Simpler, generally less expensive | More complex, often higher cost |

For most users replacing a switch on a standard compressor, a fixed-range switch matching the original specs is the best and safest option. Tinker only if you fully understand your system’s requirements.

Pro Tip: Take a clear photo of your old switch and its wiring before disconnecting anything. This is an invaluable reference during installation and ensures you reconnect the new switch correctly.

Common Installation Mistakes and Safety Precautions

Even with the correct part, improper installation can lead to failure. Understanding these common pitfalls is crucial for a successful repair. Always prioritize safety when working with electrical components and pressurized systems.

Critical Safety Warnings Before You Begin

Never underestimate the risks involved. Comply with these non-negotiable safety steps.

- Disconnect All Power: Unplug the compressor AND flip the circuit breaker. Verify power is off with a multimeter at the terminals.

- Depressurize the Tank: Open the drain valve completely and trigger the tank’s safety valve to ensure zero air pressure remains.

- Use Proper Tools: Employ correct wrenches for fittings to avoid stripping. Use wire strippers and screwdrivers that fit the terminals snugly.

Avoiding Frequent Installation Errors

Steer clear of these mistakes that compromise function and safety.

Over-tightening Connections: This is a major cause of failure. Over-tightening the pressure switch’s port can crack the housing. It can also damage the tank’s female threads, leading to costly repairs.

Incorrect Wiring: Reversing the line and load wires or misplacing the ground can cause immediate failure or a shock hazard. Always follow the diagram on the new switch or your reference photo.

Ignoring the Unloader Valve Line: If your old switch had a small tube (the unloader line), the new switch must have a port for it. Forgetting to reconnect it causes the motor to struggle on restart and creates excessive wear.

Safety Summary: The rule is Zero Energy State—no electrical pressure and no air pressure. Double-check every connection. If you are unsure about the wiring, consult a qualified electrician.

Post-Installation Testing Procedure

Do not assume the job is done after assembly. A proper test cycle is essential.

- Ensure the drain valve is closed and the switch is in the OFF position.

- Reconnect power and turn the switch ON. Listen for normal motor operation.

- Observe the pressure gauge. The motor should shut off (cut-out) at the specified high pressure.

- Use an air tool to drop pressure. The motor should automatically restart (cut-in) at the correct low pressure.

When to Replace vs. Repair Your Pressure Switch

Not every faulty switch needs immediate replacement. Some issues are simple fixes, while others demand a new part. Diagnosing the problem correctly saves time and money.

Troubleshooting Common Pressure Switch Problems

Identify the symptom to determine the best course of action. Start with these diagnostic checks.

- Compressor Won’t Start: Check for power at the outlet and the switch terminals. Listen for a faint hum, which may indicate a stuck internal contact.

- Compressor Won’t Stop: This is dangerous and often a failed diaphragm or internal mechanism. Immediately shut off power and depressurize the tank.

- Short Cycling (Rapid On/Off): This can be a switch issue, but also check for significant air leaks in the system or a faulty check valve at the tank.

Repairable Issues vs. Mandatory Replacement

Use this guide to decide between a quick fix and buying a new switch.

| Symptom / Issue | Possible Repair | Likely Needs Replacement |

|---|---|---|

| Loose Electrical Terminal | Tighten the terminal screw securely. | If terminal is burnt or damaged. |

| Minor Air Leak at Port | Apply fresh thread sealant (Teflon tape/paste). | If housing is cracked or threads are stripped. |

| Incorrect Pressure Setting | Adjust the set screw (if switch is adjustable). | If adjustment does not change pressure. |

| Motor Hums but Doesn’t Start | Tap switch body lightly to free contacts. | If tapping doesn’t work; contacts are welded or worn. |

Signs You Must Install a New Switch

Certain red flags mean repair is not a safe or viable option. Recognize these critical failure signs.

- Visible Damage: Cracks in the housing, severe corrosion, or melted/burnt plastic are clear indicators.

- Internal Failure: A ruptured diaphragm or broken spring mechanism cannot be reliably repaired by most users.

- Age and Intermittent Operation: If the switch is very old and fails unpredictably, replacement is the most reliable solution.

Diagnosis Tip: Before condemning the switch, rule out other causes. Test the pressure release valve and check for tank leaks. A faulty pressure gauge can also mimic switch problems.

Expert Tips for Maintaining Your Pressure Switch

Proper maintenance extends the life of your new pressure switch and the entire compressor. A little preventative care prevents major downtime. These expert practices ensure reliable, long-term operation.

Routine Maintenance Checklist

Incorporate these simple tasks into your regular compressor service routine. They take minutes but save hours of repair.

- Monthly Visual Inspection: Check for moisture, oil accumulation, or dust around the switch. Clean with a dry cloth and ensure the air intake filter is clean.

- Check for Air Leaks: With the tank pressurized and the motor off, listen for hissing at the switch port and unloader valve. Use soapy water to pinpoint tiny leaks.

- Verify Pressure Settings: Periodically confirm the cut-in and cut-out pressures with a known-accurate gauge. Drift can indicate internal wear.

- Keep Electrical Connections Tight: Vibration can loosen terminal screws over time. With power OFF, check and snug connections annually.

Optimizing Switch Performance and Longevity

Go beyond basic checks with these pro-level strategies for peak performance.

Manage Moisture and Condensation: Water is the enemy of metal components and electrical contacts. Always drain your air tank after use. Consider adding an inline filter/dryer before the switch if you operate in a humid environment.

Mitigate Vibration Damage: Compressor vibration stresses electrical connections and internal parts. Ensure the compressor is on a stable, level surface. You can install an anti-vibration pad under the unit to reduce shock.

Use the Correct Accessories: When sealing threads, use thread sealant paste designed for compressed air systems, not standard Teflon tape which can shred and clog small orifices. Ensure any replacement tubing for the unloader line is rated for air pressure.

Pro Longevity Tip: Install a pressure switch cover or a small drip loop in the unloader line if present. This simple shield protects the switch from direct exposure to water, oil, and physical impact in busy workshops.

When to Call a Professional

Know your limits. Some situations require expert intervention for safety and warranty protection.

- If you are uncomfortable with any electrical diagnosis or wiring.

- When the compressor is still under manufacturer’s warranty (unauthorized repair may void it).

- If repeated switch failures indicate a deeper problem with the motor, pump, or check valve.

Finding the Right Part: OEM vs. Universal Replacement

Once you know your specs, you face a final choice: buy the original part or a compatible one. Each option has distinct advantages and trade-offs. Your decision impacts cost, availability, and ease of installation.

OEM (Original Equipment Manufacturer) Switches

This is the exact part made by your compressor’s brand. It guarantees a perfect match in every dimension.

- Guaranteed Compatibility: Fit, function, and wiring are identical to the original. This eliminates all guesswork.

- Potential Drawbacks: Often more expensive. May have limited availability for older or discontinued compressor models.

- Best For: Users who want a plug-and-play solution and are willing to pay a premium for certainty, especially on newer equipment.

Universal or Compatible Replacement Switches

These are third-party switches designed to match common specifications across many brands.

- Cost-Effective & Widely Available: Typically less expensive than OEM and stocked by many retailers. Great for common pressure ranges like 30-50 PSI.

- Requires Verification: You must diligently cross-reference all specifications (voltage, HP, port size, unloader). Physical dimensions may differ slightly.

- Best For: DIYers comfortable with matching specs, owners of older compressors where OEM parts are obsolete, or those on a budget.

How to Source Your Replacement Switch

Use this strategic approach to find the part you need quickly and reliably.

- Start with Your Compressor Model: Search online for “[Your Compressor Brand & Model] pressure switch.” This may yield both OEM and compatible options.

- Use Your Gathered Specs: If OEM is unavailable, search by your key specs (e.g., “120V 1.5 HP 30-50 PSI pressure switch 1/4 NPT”).

- Check Reputable Suppliers: Look at industrial supply houses, specialty compressor shops, and major online retailers. Read product Q&A sections for fit notes.

- Consult the Community: Forums for your specific compressor brand can be invaluable for proven part numbers and recommendations.

Sourcing Tip: When buying a universal switch, choose a reputable brand like Square D, Furnas, or Condor over a no-name part. The slight cost increase buys significant gains in reliability, safety, and longevity.

Advanced Considerations and Special Applications

Standard switches cover most needs, but specialized compressors demand unique solutions. Understanding these advanced factors is crucial for commercial or high-performance systems. This knowledge prevents underperformance and equipment damage.

High-Pressure and Industrial Compressor Switches

Standard switches fail quickly under extreme conditions. Industrial applications require robust components.

- Pressure Ratings: Industrial compressors (150+ PSI) need switches rated for that continuous pressure. A 150 PSI switch on a 200 PSI system is a safety hazard.

- Durability Construction: Look for all-metal housings, stainless steel springs, and sealed mechanisms to withstand vibration, heat, and corrosive environments.

- Motor Starters: Large HP motors (over 5 HP) often use a pressure switch to activate a separate magnetic motor starter, not carry the load directly.

Specialized Switch Types and Features

Beyond basic on/off control, modern switches offer enhanced functionality.

| Switch Type | Key Feature | Typical Application |

|---|---|---|

| Differential-Only Switch | Adjusts the difference (spread) between cut-in and cut-out. | Fine-tuning cycle frequency for specific tools or processes. |

| Pressure Switch with Gauge Port | Has an extra port to connect a pressure gauge directly. | Provides a precise, localized pressure reading at the switch. |

| Explosion-Proof Enclosure | Housing contains any internal spark. | Mandatory for use in hazardous locations with flammable vapors or dust. |

Integrating with System Upgrades

Modifying your air system may require a switch upgrade. Plan these changes holistically.

- Increasing Tank Pressure: Upgrading to a higher-pressure pump and tank requires a matching pressure switch and safety valve. Never exceed the switch’s rated maximum.

- Adding a Second Tank: The pressure switch typically monitors the primary tank. Ensure its capacity and cycle rate can handle the increased total air volume.

- Automation and Monitoring: Some advanced switches offer electrical signals for remote monitoring or integration into automated control panels.

Critical Rule: For any system modification, especially involving pressure increases, the pressure switch and the safety relief valve must be rated for the new maximum system pressure. This is non-negotiable for safe operation.

Conclusion: Finding the Right Air Compressor Pressure Switch

Air compressor pressure switches are not universal, but finding the correct one is straightforward with the right knowledge. By matching voltage, horsepower, pressure range, and port size, you ensure safe and reliable operation.

The key takeaway is to always verify your old switch’s specifications before purchasing any replacement. Use our step-by-step guide to diagnose, select, and install the perfect part for your system.

Take action by reviewing your compressor’s manual and inspecting your current switch today. Proper maintenance of this critical component will extend the life of your entire air system.

With this comprehensive guide, you can confidently tackle this repair, saving time and money while ensuring your workshop runs smoothly.

Frequently Asked Questions about Air Compressor Pressure Switches

What is the main function of an air compressor pressure switch?

The pressure switch is the brain of your compressor’s automatic operation. It monitors tank pressure and turns the motor on and off at preset levels. This maintains consistent air pressure for your tools while preventing dangerous over-pressurization.

It achieves this through an internal diaphragm that moves with pressure changes. This movement opens or closes electrical contacts to control power to the motor, creating a safe and efficient cycle.

How do I know if my pressure switch is bad?

Common failure signs include the compressor not starting, not stopping (running continuously), or short cycling rapidly. You may also hear a humming sound without the motor engaging, indicating stuck internal contacts.

Visible damage like cracks, severe corrosion, or burnt terminals are clear indicators. Before replacing the switch, rule out other issues like a tripped breaker, faulty power cord, or significant air leaks in the system.

Can I adjust the cut-in and cut-out pressure on any switch?

No, only adjustable pressure switches allow this modification. Many OEM switches have a fixed, non-adjustable range (e.g., factory-set to 30-50 PSI). Attempting to adjust a fixed switch will damage it.

If your switch has one or two adjustment nuts or screws, it is likely adjustable. Always refer to the manufacturer’s instructions, as improper adjustment can affect motor longevity and safety valve operation.

What happens if I install a pressure switch with the wrong voltage rating?

Using a switch with a lower voltage rating than your compressor is extremely dangerous. It will likely fail immediately, potentially welding the contacts closed or causing a fire hazard. The switch cannot handle the electrical load.

Using a higher voltage-rated switch (like a 240V switch on a 120V circuit) may work temporarily but is not recommended. The internal components may not activate reliably at the lower voltage, leading to erratic performance and premature failure.

Why does my new pressure switch keep tripping the reset button?

A tripping reset button typically indicates an overload condition. This is often caused by installing a switch with an insufficient horsepower (HP) or amperage (A) rating for your compressor motor. The motor’s starting current exceeds the switch’s capacity.

Other causes include a failing motor drawing too much current (locked rotor) or a short circuit in the wiring. Always ensure the switch’s HP rating matches or exceeds your motor’s specifications.

What is the difference between a pressure switch with and without an unloader valve?

A switch with an unloader valve has a small port for a tube that releases air pressure from the pump head after shutdown. This prevents the motor from struggling against back-pressure on the next start, reducing wear.

If your original setup has an unloader line, you must replace it with a switch that has this feature. Omitting it causes hard starting and excessive strain. Many universal switches include this as a standard feature.

How often should I replace my air compressor pressure switch?

There’s no fixed timeline; replacement is based on condition, not age. A quality switch with proper maintenance can last for many years. However, they are a wear item due to constant electrical arcing and mechanical movement.

Replace the switch when it shows signs of failure or erratic behavior. Proactive replacement during a major compressor overhaul is also a good practice to ensure system reliability.

Is it safe to bypass a faulty pressure switch temporarily?

No, bypassing a pressure switch is extremely dangerous and should never be done. This disables the automatic shut-off, allowing the tank to pressurize indefinitely until the safety valve releases or the tank ruptures.

Running a compressor without a functional pressure switch risks catastrophic tank failure, which can cause property damage, injury, or death. Always repair or replace a faulty switch immediately and operate the compressor only with it correctly installed.